Quality Policy

We are committed to manufacture and supply fabricated product, machined components by safe and cost effective methods to achieve customer satisfaction through dedicated team work, Innovation and continual Improvements.

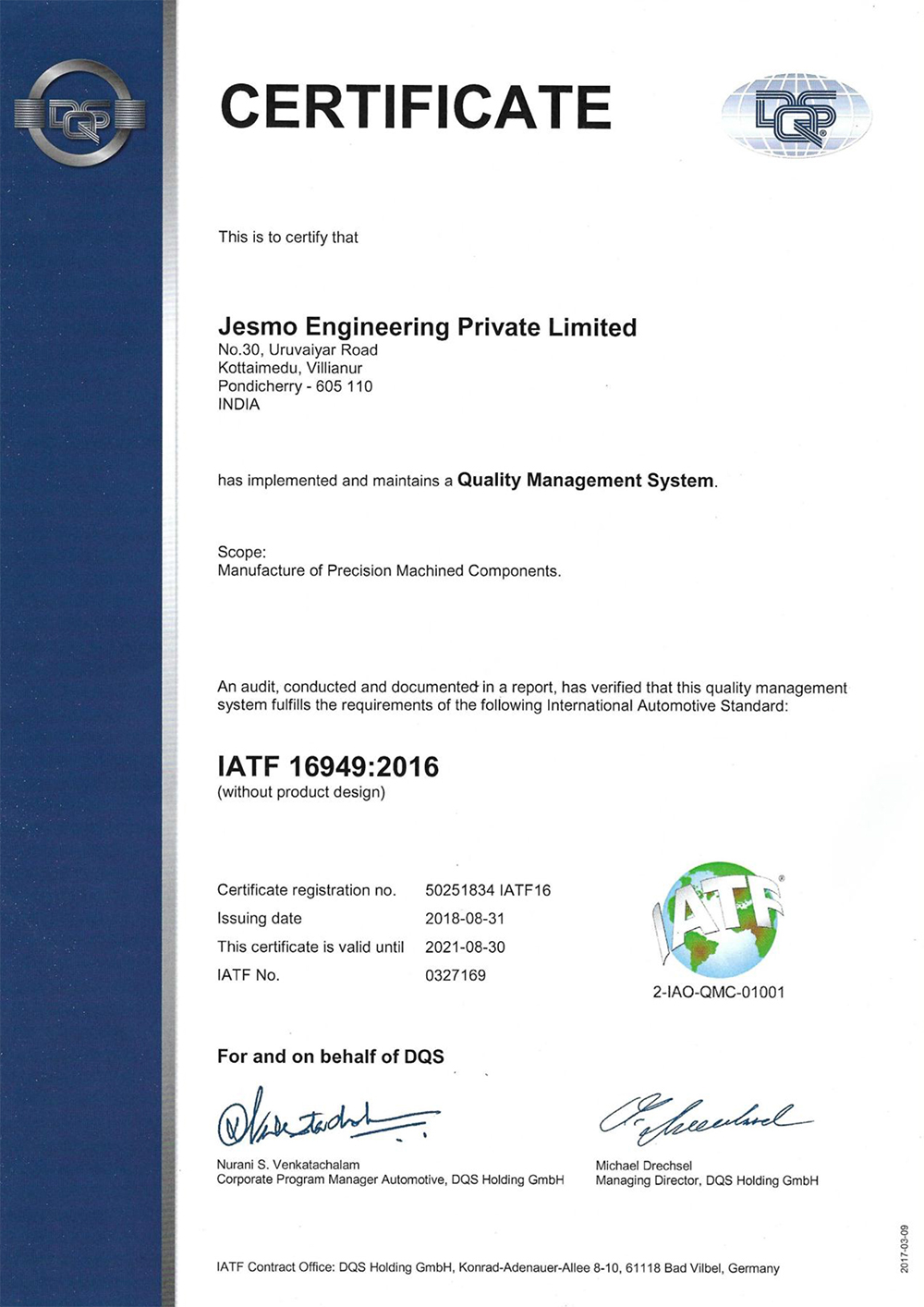

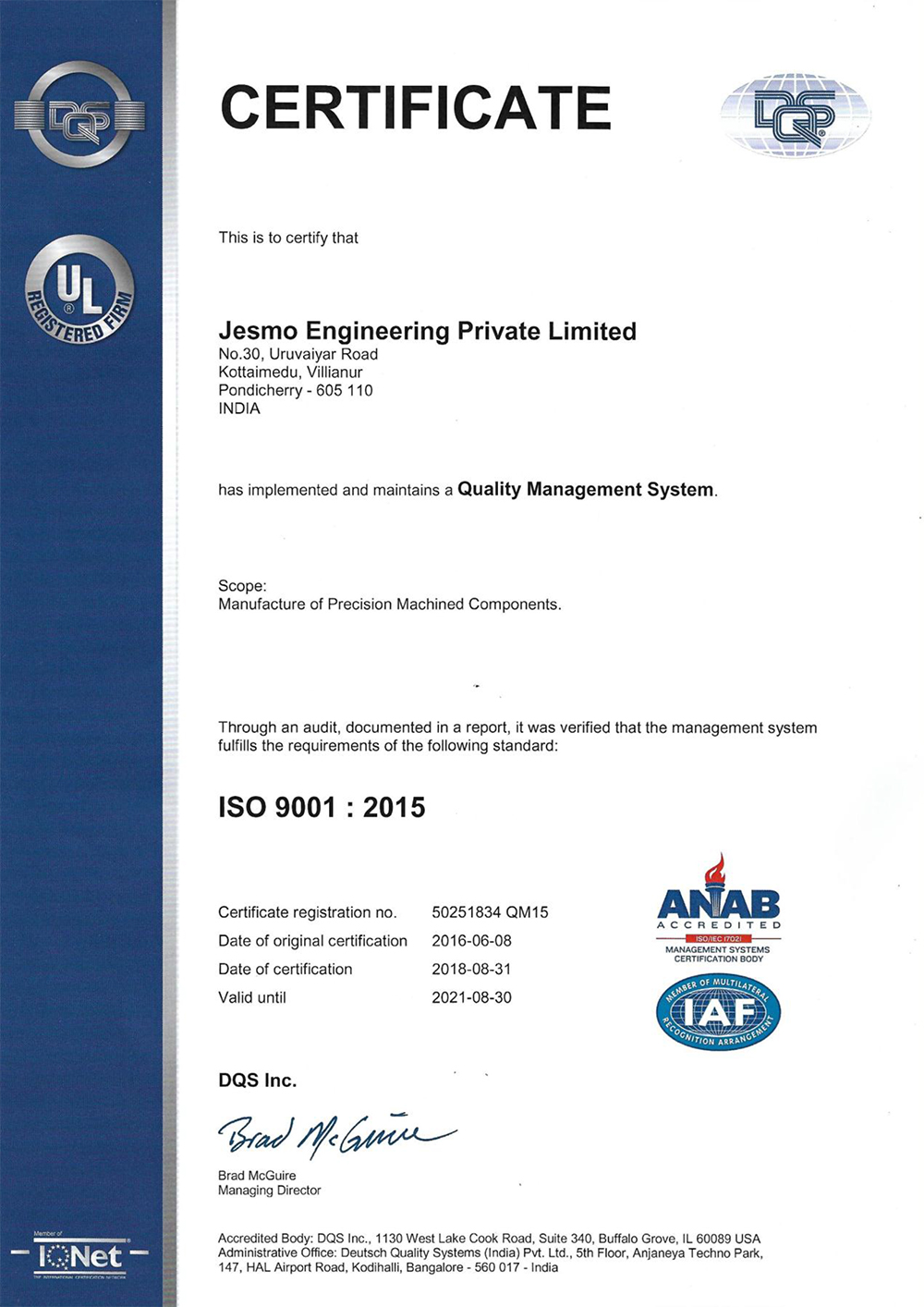

- Follows ISO 9001:2015 & IATF 16949:2016 Quality System Requirements

- Planning product quality through APQP Process

- Detecting Failures through Incoming, In process, Final & Layout Inspectionsrs)

- Analyzing Failures through G8D and 5-Why Analysis

- Conducting PPAP and Product Trial Run

- Making the process capable and stable through Cpk and Ppk studies

- Inspection Aids qualified through Measurement system analysis (Gauge R&R)

- Implementing Poke-yoke, Kaizen and 5S

- Improving the process efficiency and effectiveness through OEE, MTBF & MTTR calculation

Quality Assurance:

Quality Controls

We have successfully built a very competent team backed by world class infrastructure.

- In house standards room facility.

- Follows National Accreditation Board for Testing and Calibration Laboratories (NABL) requirements.

- Equipped with adequate Masters.

- Inspection Aids qualified through Measurement system analysis.

- Stringent adherence to Calibration schedule.

Standard Room:

- Profile Projector – Omega

- Digital height gauge – Baker

- Coat meter (power coating)– Baker

- Bevel protector

- Machining Facility

Inspection Facility:

Quality Assurance